Direct Glue to Film Printing, simple procedure with low equipment requirements. No need of pretrement, and no need of hot melt powder. Print directly to transfer film, transfer onto fabric via heat press to achieve excellent elasticity and resistant to stretch, finished product that feels good to the touch, and has good color fastness. Excellent whiteness and vibrant color fastness on dark garments.

| Textile Printing | Description | DTG | DTF | DGF🏆 |

How |

Print directly on the fabric | ✓ | ||

|---|---|---|---|---|

| Print on the film and apply the hot melt powder on it Melt the powder and transfer the image to the fabric | ✓ | |||

| Print glue ink on the film and transfer the image to the fabric | ✓ | |||

Application |

Fabric/ T-shirt(50-100% cotton) | ✓ | ✓ | |

| Polyester, cotton, silk or synthetic fibers | ✓ | ✓ | ||

Advantages |

High efficiency | ✓ | ✓ | |

| Small machine size | ✓ | ✓ | ||

| Good breathability | ✓ | ✓ | ||

| arious fabric | ✓ | ✓ | ||

| Competitive ink price | ✓ | ✓ | ||

| Good printing performance on light fabric | ✓ | ✓ | ||

| No pre-treatment | ✓ | ✓ | ||

| No powdering | ✓ | ✓ | ||

| No curing oven to melt the powder | ✓ | ✓ | ||

| Simple procedure | ✓ |

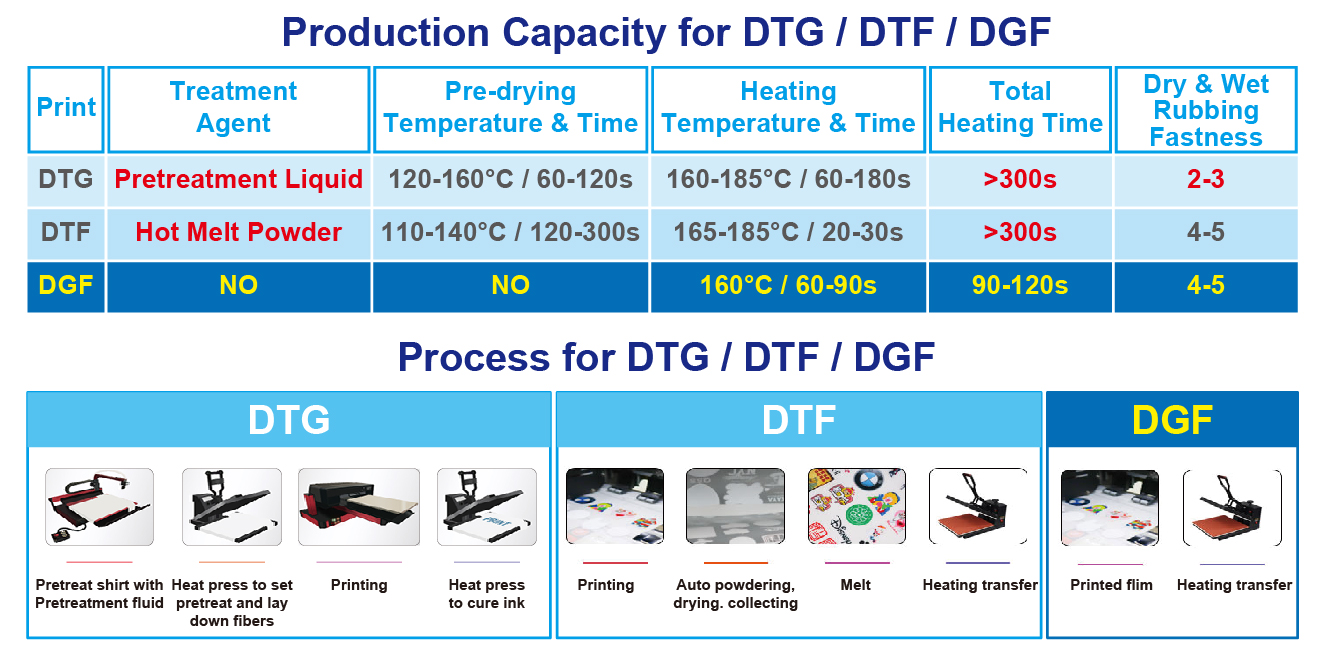

| Description | Treatment Agent | Pre-drying Temperature & Time | Heating Temperature & Time | Total Heating Time | Dry & Wet Rubbing Fastness | DTG | Pretreatment Liquid | 120-160℃ / 60-120s | 160-185℃ / 60-180s | >300s | 2-3 | DTF | Hot Melt Powder | 120-160℃ / 60-120s | 110-140℃ / 120-300s | >300s | 4-5 |

| DGF🏆 | NO | NO | 160℃ / 60-90s | 90-120s | 4-5 |

| Head Type | Head Model |

|---|---|

| EPSON | I3200 |